Distribution nozzles For Cooling towers

Product Details:

- Product Type Distribution nozzles

- Color Different color

- Usage industrial

- Material Other

- Application commercial

- Type nozzles

- Warranty -

- Click to View more

Distribution nozzles For Cooling towers Price And Quantity

- 1000 Number

- 180.0 INR/Number

Distribution nozzles For Cooling towers Product Specifications

- Other

- Different color

- -

- commercial

- nozzles

- Distribution nozzles

- industrial

Distribution nozzles For Cooling towers Trade Information

- Cash in Advance (CID)

- 30 Number Per Month

- 1 Week

- All India

Product Description

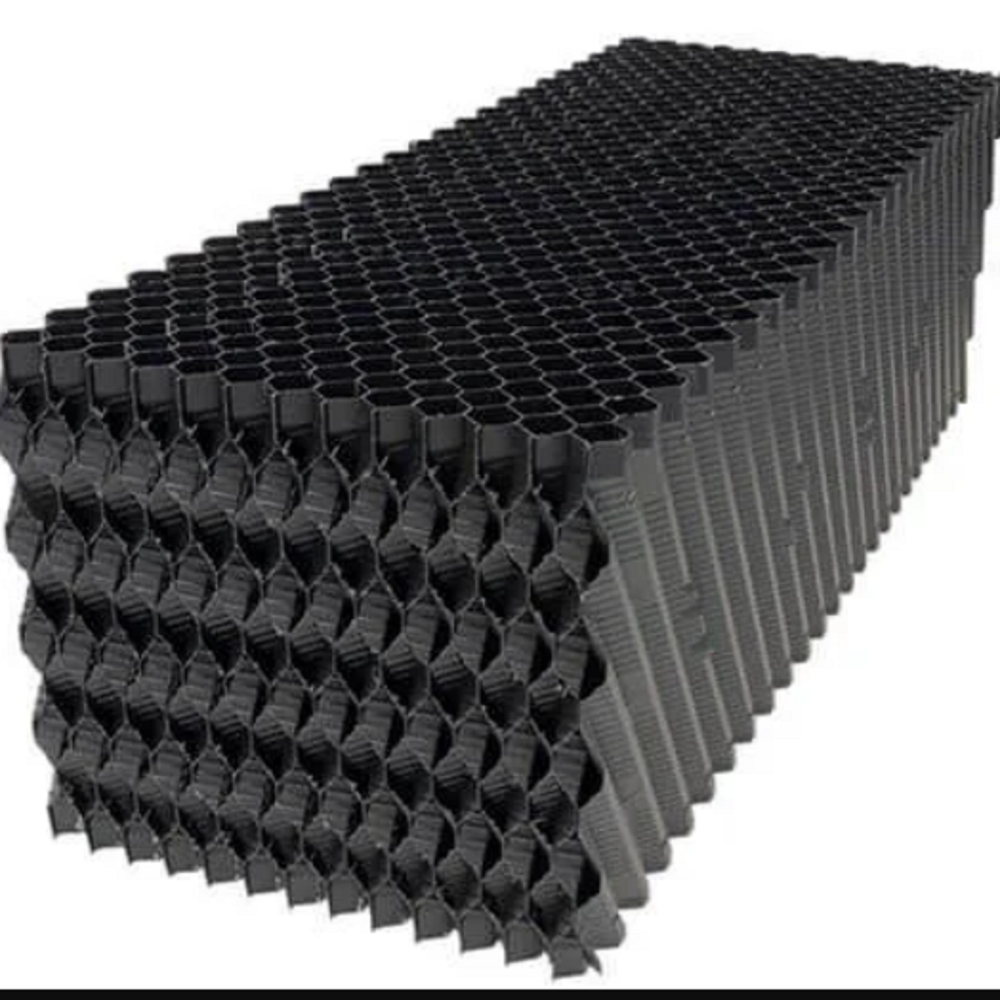

Cooling tower distribution nozzles arespray nozzles that evenly distribute water from the process to the heat transfer fill, a crucial part of the cooling process in wet cooling towers.

Here's a more detailed explanation:

- Purpose:

The primary function of these nozzles is to transfer hot water from the process to the heat transfer fill, ensuring efficient cooling.

- Function:

They are designed to disperse water evenly and constantly, covering the fill pack to maximize heat exchange.

- Materials:

Cooling tower nozzles are typically made of PVC, glass, or ceramic, with some being high-temperature resistant and having non-clogging designs.

- Types:

Cooling tower nozzles come in both cross-flow and counter-flow designs.

- Importance:

Proper nozzle selection and maintenance are crucial for efficient water distribution, which directly impacts cooling tower performance.

- Troubleshooting:

Clogged or improperly adjusted nozzles can lead to uneven water distribution, reducing cooling efficiency and potentially causing dry spots or excessive water loss.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+