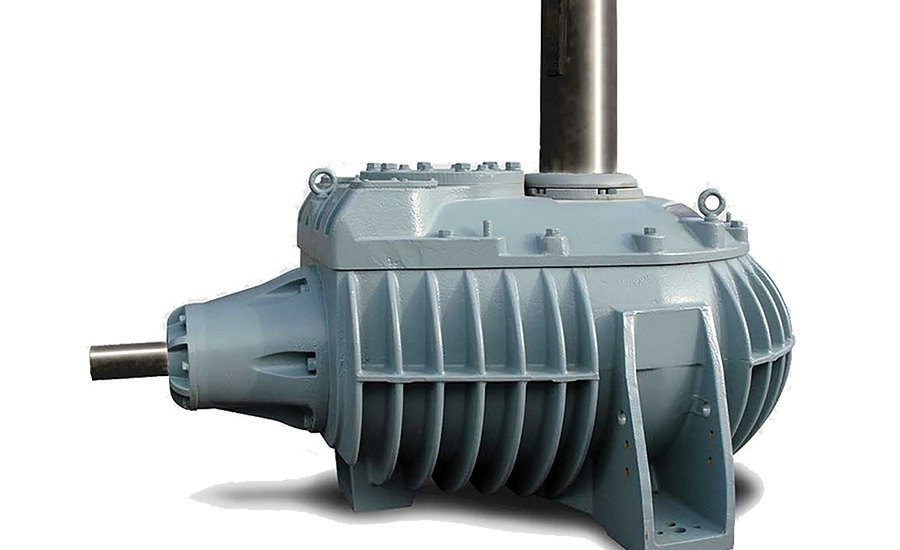

cooling tower drive shaft assembly

Product Details:

- Weight 15 Kilograms (kg)

- Application commercial

- Usage industrial

- Height 20 Foot (ft)

- Color Silver

- Width 12.5 Millimeter (mm)

- Length 4.5 Meter (m)

- Click to View more

cooling tower drive shaft assembly Price And Quantity

- 1 Number

- 10000.0 INR/Number

cooling tower drive shaft assembly Product Specifications

- 15 Kilograms (kg)

- 20 Foot (ft)

- Silver

- industrial

- commercial

- yes

- 12.5 Millimeter (mm)

- 4.5 Meter (m)

- Metal

cooling tower drive shaft assembly Trade Information

- Cash in Advance (CID)

- 30 Number Per Month

- 4 Week

- All India

Product Description

A cooling tower drive shaft assemblytransmits rotational energy from the motor to the fan, circulating air for heat dissipation and is typically made of corrosion-resistant materials like stainless steel.

Here's a more detailed breakdown:

- Function:

The primary function of a cooling tower drive shaft is to transmit power from the motor to the fan blades, enabling them to rotate and draw air through the cooling tower for cooling.

- Materials:

Cooling tower drive shafts are often constructed from durable, corrosion-resistant materials like stainless steel or carbon fiber to withstand the harsh environmental conditions in and around cooling towers.

- Design:

- Single-piece design:Some drive shafts are designed as single-piece units for enhanced strength and reliability.

- Flexible couplings:Flexible couplings are used to connect the drive shaft to the motor and gear reducer, allowing for some misalignment and reducing stress on the shaft.

- Dynamic balancing:The drive shaft assembly is dynamically balanced to ensure smooth and vibration-free operation.

- Arrestors and guards:Drive shaft arrestors and coupling guards are often included to protect equipment and personnel from potential hazards.

- Maintenance:

Regular maintenance, including inspections for wear and tear and proper lubrication, is essential to ensure the drive shaft assembly operates reliably.

- Types:

- HDG/SS (Hot Dip Galvanized/Stainless Steel):These are common materials for drive shafts, offering good corrosion resistance and durability.

- Carbon Composite Fiber:Some cooling tower drive shafts are made from carbon composite fiber, offering a lightweight and strong alternative.

- Benefits of composite drive shafts:

- Low maintenance due to no intermediate couplings or bearings.

- Lightweight and easy to install.

- Robust construction.

- Specifics of Paharpur drive shafts:

- Dynamically balanced for smooth operation.

- Single-piece units.

- No lubrication required.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+