FRP cooling tower body

தயாரிப்பு விவரங்கள்:

- பயன்பாடு industrial

- கலர் Blue

- பொருள்

- விண்ணப்பம் commercial

- தயாரிப்பு வகை cooling tower

- கண்டிஷன்

- மேலும் பார்க்க கிளிக் செய்யவும்

விலை மற்றும் அளவு

- 100

தயாரிப்பு விவரக்குறிப்புகள்

- cooling tower

- Blue

- commercial

- industrial

வர்த்தகத் தகவல்கள்

- மாதத்திற்கு

- வாரம்

தயாரிப்பு விளக்கம்

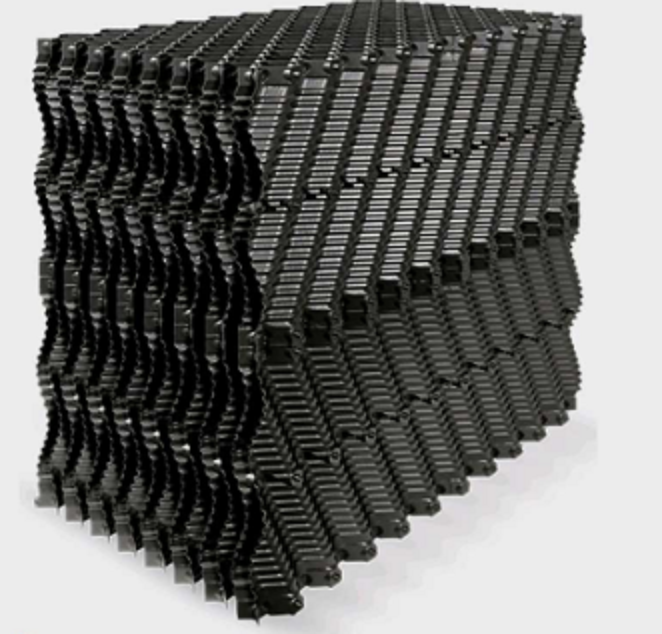

FRP (Fiberglass Reinforced Plastic) cooling tower bodies areconstructed from a durable, lightweight, and corrosion-resistant composite material, offering advantages like easy maintenance and long-term durability, making them suitable for various industrial applications.

Here's a more detailed description:

Materials and Construction:

- FRP Composition:

FRP cooling towers are made by combining fiberglass and resin materials, resulting in a strong and lightweight structure.

- Corrosion Resistance:

The FRP material is highly resistant to corrosion, rust, and degradation, making it ideal for environments exposed to water, chemicals, and harsh conditions.

- Lightweight and Durable:

FRP offers a high strength-to-weight ratio, making it easier to transport, handle, and install compared to traditional materials like concrete or steel.

- Design Flexibility:

FRP can be molded into various shapes and sizes, allowing for customized cooling tower designs tailored to specific project requirements.

- Maintenance:

The smooth surface of FRP makes it easy to clean and maintain, reducing the need for regular repainting or refinishing.

Benefits of FRP Cooling Towers:

- Longevity:

FRP cooling towers are known for their long service life and durability, requiring minimal maintenance.

- Resistance to Harsh Conditions:

FRP can withstand harsh environmental conditions, including exposure to moisture, chemicals, and UV radiation.

- Energy Efficiency:

FRP cooling towers can be designed for energy efficiency, reducing operational costs.

- Easy Installation:

The lightweight nature of FRP allows for easier installation, even in areas with limited access or structural limitations.

- Aesthetic Appeal:

FRP cooling towers can be designed in various colors and shapes to match the surrounding architectural style.

Applications:

- Industrial Cooling:

FRP cooling towers are commonly used in industrial applications where water is the primary heat transfer medium, such as in power plants, refineries, and chemical plants.

- HVAC Systems:

They can also be used in HVAC systems to cool large buildings and facilities.

- Other Applications:

FRP cooling towers can be used in various other applications, including food processing, agriculture, and manufacturing.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+