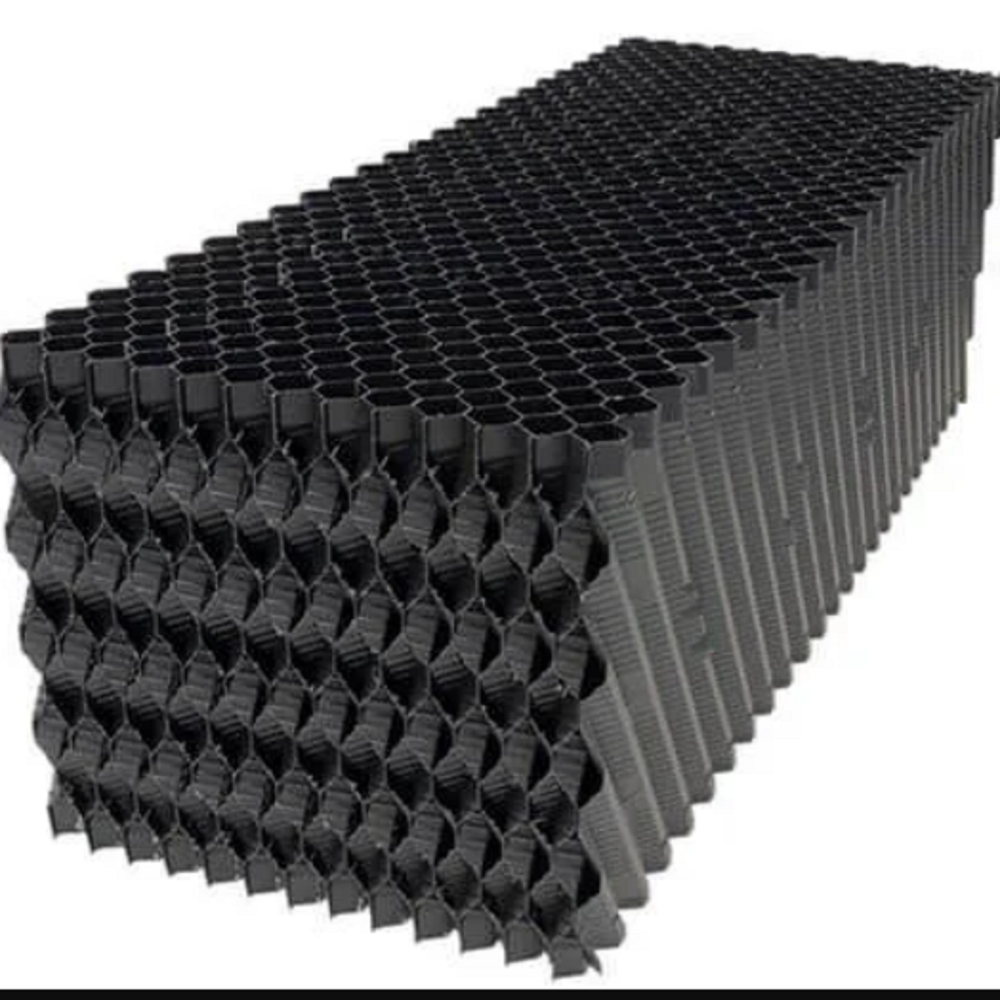

Drift eliminator for Cooling tower

தயாரிப்பு விவரங்கள்:

- தயாரிப்பு வகை Cooling Tower Drift Eliminator

- கலர் BLACK

- பயன்பாடு industrial

- விண்ணப்பம் commercial

- பொருள்

- உத்தரவாதத்தை -

- மேலும் பார்க்க கிளிக் செய்யவும்

விலை மற்றும் அளவு

- 100

தயாரிப்பு விவரக்குறிப்புகள்

- BLACK

- -

- commercial

- Cooling Tower Drift Eliminator

- industrial

வர்த்தகத் தகவல்கள்

- வாரத்திற்கு

- வாரம்

தயாரிப்பு விளக்கம்

A cooling tower drift eliminator isa device designed to capture and prevent large water droplets, or "drift," from escaping the cooling tower's exhaust air stream, minimizing water loss and potential environmental impact.

Here's a more detailed explanation:

Function:

- Capturing Drift:

Drift eliminators are strategically placed on the discharge side of a cooling tower to intercept water droplets that are entrained in the air stream.

- Preventing Escape:

They work by causing the droplets to change direction, lose velocity, impact the eliminator walls, and fall back into the tower, preventing them from escaping into the environment.

- Maintaining Efficiency:

Efficient drift eliminators can keep drift losses to less than 0.001% of the recirculating water flow rate.

Materials and Design:

- Common Materials:

Drift eliminators are typically made from PVC or polypropylene (PP) for durability and resistance to water and chemicals.

- Blade-Type:

Blade-type eliminators are designed with blades that are light in weight but strong in durability.

- Cellular/Labyrinthine:

Other designs include cellular or labyrinthine structures to create a more complex path for the air, further enhancing droplet capture.

- Fill-Integrated:

Some designs integrate fillings like carbon black into the main material to enhance lifespan and protect against corrosion.

Importance:

- Water Conservation:

By minimizing drift losses, drift eliminators help conserve water, a valuable resource.

- Environmental Protection:

They prevent the discharge of water droplets containing impurities or chemicals into the environment.

- Reduced Corrosion:

By preventing the escape of water droplets, drift eliminators help to reduce corrosion of electrical parts and piping systems.

- Legionella Prevention:

They can help prevent the spread of Legionella bacteria, which can be found in cooling towers.

- Compliance:

Some regulations and standards require the use of effective drift eliminators in cooling towers.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+