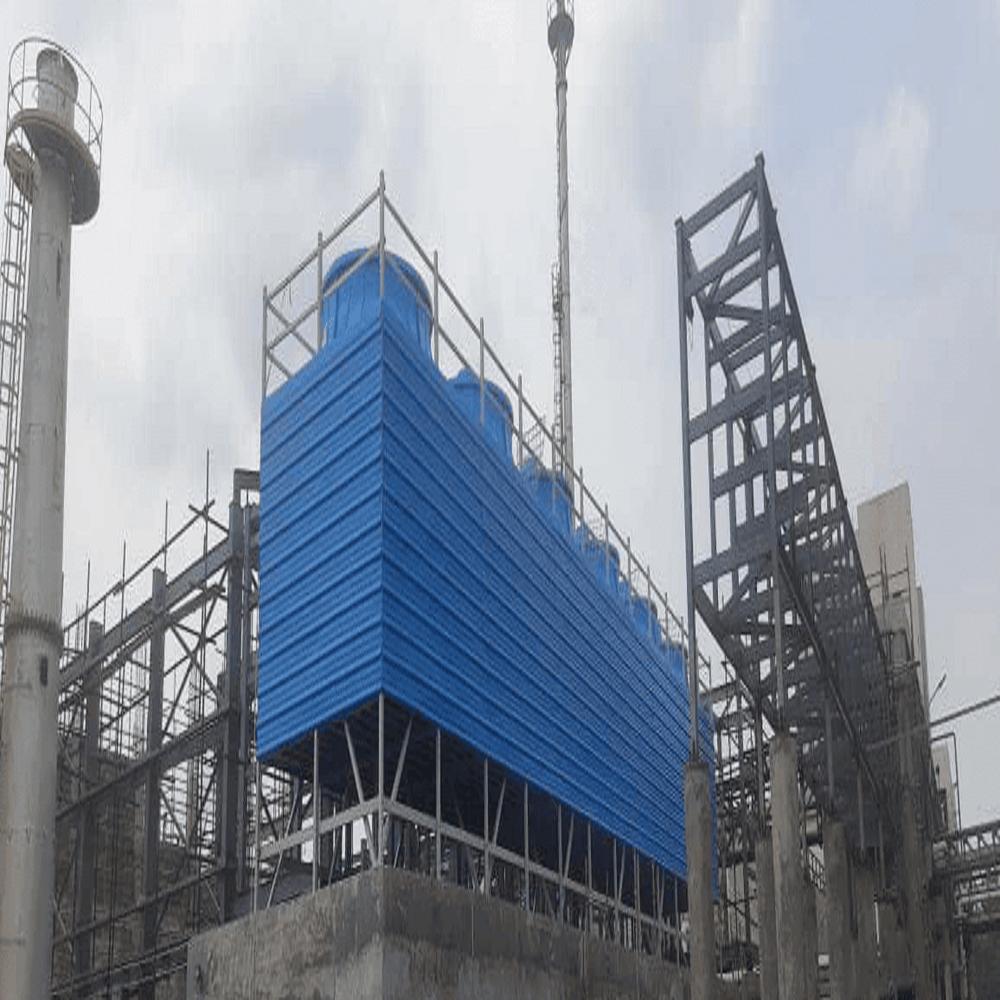

FRP Materials for cooling towers

Product Details:

- Usage industrial

- Material FRP

- Product Type FRP Materials for cooling towers

- Power Supply electrical

- Warranty yes

- Click to View more

FRP Materials for cooling towers Price And Quantity

- 100 Number

- 100000.0 INR/Number

FRP Materials for cooling towers Product Specifications

- electrical

- industrial

- yes

- FRP Materials for cooling towers

- FRP

FRP Materials for cooling towers Trade Information

- Cash in Advance (CID)

- 30 Number Per Month

- 2 Week

- All India

Product Description

FRP (Fiberglass Reinforced Polymer) cooling towers are a popular choice for industrial cooling applications due to theirlightweight, durable, corrosion-resistant, and low-maintenance nature, making them ideal for harsh environments.

Here's a more detailed description:

What is FRP?

- FRP is a composite material made of a polymer matrix reinforced with fibers, often glass fibers.

- It's also known as fiberglass reinforced polymer (FRP) or glass fiber reinforced plastic (GRP).

Why use FRP in cooling towers?

- Corrosion Resistance:

FRP excels in resisting corrosion from water, chemicals, and harsh weather conditions, unlike traditional materials like wood, concrete, or steel/aluminum.

- Durability:

FRP cooling towers have a long service life and require minimal maintenance due to their resistance to rot, rust, and degradation.

- Lightweight:

FRP is lightweight, which can simplify installation and reduce structural support requirements.

- Strength:

FRP offers a high strength-to-weight ratio, making it a robust material for cooling tower structures.

- Low Maintenance:

The non-corrosive nature of FRP means less maintenance is required, reducing operational costs.

- Versatility:

FRP can be molded into various shapes and sizes, allowing for customized cooling tower designs.

- Cost-Effectiveness:

FRP cooling towers can be more cost-effective in the long run due to their durability and low maintenance needs.

Examples of FRP Components in Cooling Towers:

- Casing panels:

FRP panels form the exterior of the cooling tower, protecting the internal components.

- Fill:

FRP can be used for the fill material, which is designed to maximize heat transfer efficiency.

- Grids and gratings:

FRP is used for walkways, ladders, and other structural components that need to withstand harsh conditions.

- Fans:

FRP can be used for fan blades, which are lightweight and resistant to corrosion.

- Motors:

FRP can be used for motor housings, which are resistant to corrosion and moisture.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+