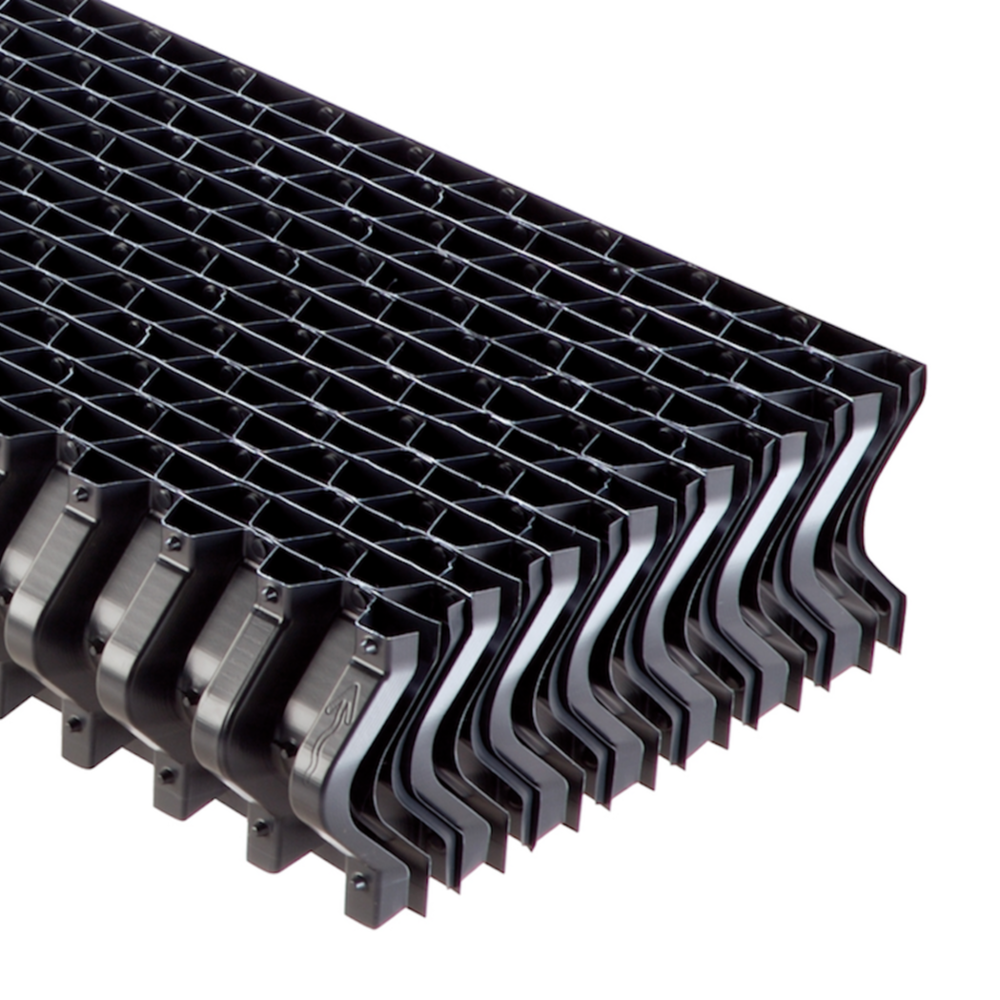

counter flow cellular drift eliminators for Cooling tower

Product Details:

- Usage industrial

- Material PVC

- Color black

- Product Type counter flow cellular drift eliminators for Cooling tower

- Condition New

- Type pvc

- Power Supply electric

- Click to View more

counter flow cellular drift eliminators for Cooling tower Price And Quantity

- 100 Number

- 20000.0 INR/Number

counter flow cellular drift eliminators for Cooling tower Product Specifications

- electric

- PVC

- black

- counter flow cellular drift eliminators for Cooling tower

- pvc

- industrial

- New

counter flow cellular drift eliminators for Cooling tower Trade Information

- Cash in Advance (CID)

- 30 Number Per Month

- 3 Week

- All India

Product Description

In counterflow cooling towers, cellular drift eliminators are baffles designed to capture and redirect water droplets entrained in the exhaust air stream, preventing them from escaping the tower and promoting water conservation and environmental compliance.

Here's a more detailed explanation:

Purpose:

Drift eliminators are crucial for reducing water loss and preventing the discharge of chemically contaminated water into the environment.

Mechanism:

They work by changing the direction of the airflow, causing water droplets to impact the eliminator surfaces and coalesce, then drain back into the tower.

Design:

Counterflow cellular drift eliminators are typically constructed from PVC or polypropylene (PP) and feature a complex system of baffles or cells.

Benefits:

Reduced Water Loss: By capturing and returning water droplets, drift eliminators minimize water consumption and associated costs.

Environmental Compliance: They help prevent the discharge of water contaminated with chemicals or other pollutants.

Improved Cooling Tower Performance: By reducing water loss, drift eliminators contribute to more efficient and reliable cooling tower operation.

Materials:

They are often made from PVC or polypropylene (PP) due to their durability, resistance to chemicals, and UV protection.

Location:

In counterflow cooling towers, drift eliminators are located on the discharge side of the tower, above the heat transfer surface and distribution layer.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+