Cooling tower Hot dip galvanizing structure

22000.0 INR/Number

Product Details:

- Material FRP

- Usage industrial

- Application COOLING TOWER

- Power Supply ELECTRICAL

- Warranty YES

- Click to View more

X

Cooling tower Hot dip galvanizing structure Price And Quantity

- 22000.0 INR/Number

- 100 Number

Cooling tower Hot dip galvanizing structure Product Specifications

- YES

- industrial

- FRP

- COOLING TOWER

- ELECTRICAL

Cooling tower Hot dip galvanizing structure Trade Information

- Cash in Advance (CID)

- 10 Number Per Month

- 2 Week

- All India

Product Description

In cooling tower construction, hot-dip galvanizingprovides a durable, corrosion-resistant zinc coating to steel components, particularly for casings, basins, and structural elements, by immersing the steel in molten zinc.

Here's a more detailed explanation:

- What is Hot-Dip Galvanizing?

- It's a process where steel is immersed in a bath of molten zinc.

- The zinc reacts with the iron in the steel, forming a series of zinc/iron intermetallic alloy layers.

- This creates a protective coating that shields the steel from corrosion.

- Why Use Hot-Dip Galvanizing in Cooling Towers?

- Cooling towers are often exposed to harsh environments and corrosive water, making corrosion protection crucial.

- Hot-dip galvanizing offers a long-lasting and cost-effective solution for protecting steel components from corrosion.

- Components Typically Hot-Dip Galvanized:

- Casings:The outer shell of the cooling tower.

- Basins:The water collection area at the bottom of the tower.

- Structural Elements:Brackets, supports, and other structural components.

- Benefits of Hot-Dip Galvanized Cooling Towers:

- Durability:The zinc coating provides excellent protection against corrosion, extending the lifespan of the tower.

- Cost-Effectiveness:Compared to using stainless steel, hot-dip galvanizing is a more economical option for corrosion protection.

- Maintenance:The zinc coating requires minimal maintenance and can withstand harsh weather conditions.

- Other Materials Used in Cooling Towers:

- Fiberglass:Used for casings and basins, providing long life and resistance to chemicals.

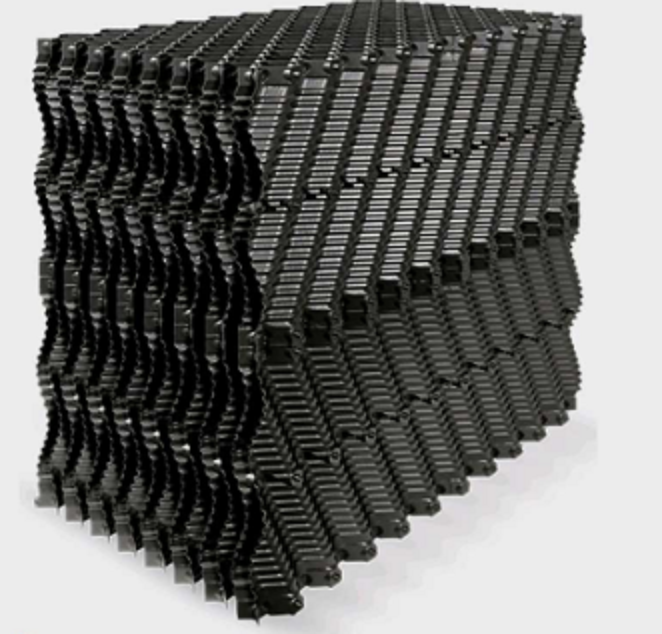

- Plastics:Used for fill, including PVC, polypropylene, and other polymers.

- Stainless Steel:Used for basins and other components in highly corrosive environments.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email